DIS Gatekeeper PA 963

Cement Retaining Collar

Plug Activated

Installation Case History

PROJECT DETAILS

Client: Major Oil and Gas Operator

Project: Installation from a Deepwater Drillship

Location: Deepwater Gulf of Mexico

CRCPA OVERVIEW

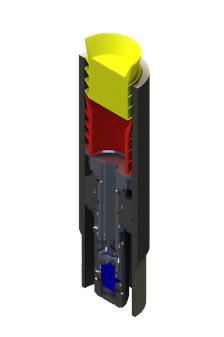

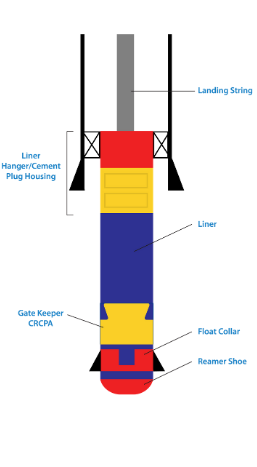

Purpose of the job was to prove the viability of the Gatekeeper Cement Retaining Collar Plug Activated (CRCPA); utilized on the 9-5/8”

production liner. Drilling Innovative Solutions, LLC presented a variant of their existing field proven Gatekeeper CRC (Inner String Variant)

in a cement plug activated version as an alternative to conventional cast iron bridge plugs. By utilizing this new technology, the client

anticipated reducing the time to complete the cement job leveraging on previous experience with the Gatekeeper CRC technology.

CHALLENGE

- Engineering and design by DIS of a plug activated cement retaining collar capable of activating at varying pressures and accommodating a wide range of cement plug designs.

- Integrating a “fail-safe” design feature in order to ensure a successful cement job should planned cementing procedures become problematic.

- Gain confidence and support from the Client’s drilling/completions team since the CRCPA had never been utilized in the field.

- Collaborate with other service companies involved in the liner installation/cementing operation (Halliburton, Baker Hughes, Weatherford, etc.) regarding the application; fully assuring integration of all components into the system to ensure job success.

DIS SOLUTION

- Design, engineer, and manufacture a variant of the inner string CRC tool that possesses identical performance characteristics in a plug activated version.

- Integrate a “fail-safe” mechanism which deploys in the event the CRCPA’s isolation sleeve closes prematurely. This fail-safe mechanism will then open and vent the trapped pressure and allow for the cement job to proceed.

- DIS manufactured a 9-5/8” OD Box by Pin VAM 21 Gatekeeper CRCPA designed to actuate at 1,800 (+/-200) PSI to be installed with the liner. All equipment was designed for up to 10,000 psi.

CRCPA COSTS

- Two 9-5/8” Gatekeeper CRCPAs $67,000

Total Costs: $67,000

SAVINGS

- Trip in hole, clean out shoe track, and circulate bottoms up 24 hours (assume spread rate of $850,000/day) $850,000

- Pull out of hole with cleanout assembly 9 hours (assume spread rate of $850,000/day) $318,750

- Run and set cast iron bridge plug 9 hours (assume spread rate of $850,000/day) $318,750

- Pull out of hole with cast iron bridge plug setting assembly 9 hours (assume spread rate of $850,000/day) $318,750

Total Savings: $1,806,000 (51 hours)

NET SAVINGS: $1,739,000

CONCLUSIONS

The biggest issue for DIS was the design, manufacture and testing of a “fail safe” mechanism that was not included in the original design and testing. After much discussion with all parties involved regarding job requirements the inclusion of the “fail safe” was deemed to be necessary. The “fail safe” would only be utilized in the event the mechanical isolation device closes prematurely. The “fail safe” mechanism

is now a standard feature on the Gatekeeper CRCPA. The success of this field application proved that the Gatekeeper CRCPA provides significant time and cost savings over conventional cast iron bridge plugs.