The Guardian Cement Float Equipment

The Guardian Cement Float Equipment includes our patented Piloted Ball Technology.

We developed The Guardian to withstand a multitude of well cementing conditions to ensure consistent performance versus the wide-range success rate of traditional cement float equipment. It uses Drilling Innovative Solutions’ patent-pending, field-proven flapper actuated ball valve technology to ensure consistent performance in a range of environments.

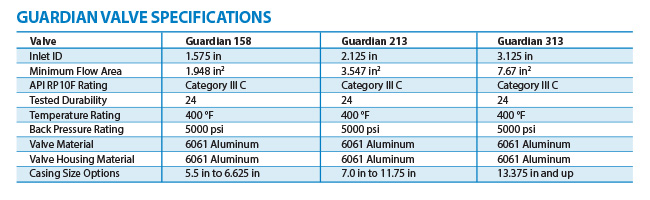

All float equipment is designed and tested to API RP10F Category IIIC standards ensuring the highest product quality. The Guardian is available in a broad range of valve sizes to accommodate standard casing sizes.

USES

- Can be used in most cementing operations including high-temperature, high-pressure (HTHP) conditions.

- The Guardian float shoe comes standard with a round nose used to guide the casing string to the desired depth.

- The Guardian float shoe is normally run with at least one Guardian float collar to provide an additional barrier against the U-tube effect of the cement, as well as allowing contaminated cement to remain in the casing string.

- The ball valve sealing allows the casing to be floated to desired depth assisting in casing run-in.

BENEFITS

- Valve is full opening, allowing for a large laminar fluid flow.

- Valve is designed utilizing an elastomeric-to-metal seal via a ball valve.

- Sealing surface is always protected from erosion via a flow tube, allowing consistent sealing after prolonged use.

- No springs are required for sealing.

- PDC and Tri-cone bit drillable.

FEATURES

- Valves available in a broad range of internal diameters.

- The Guardian float shoe can be provided with ports (up, down and/or side) and various noses for different applications.

- Available with auto-fill.

- Available in premium grade materials and connections.

- 10,000 psi valves available upon request.